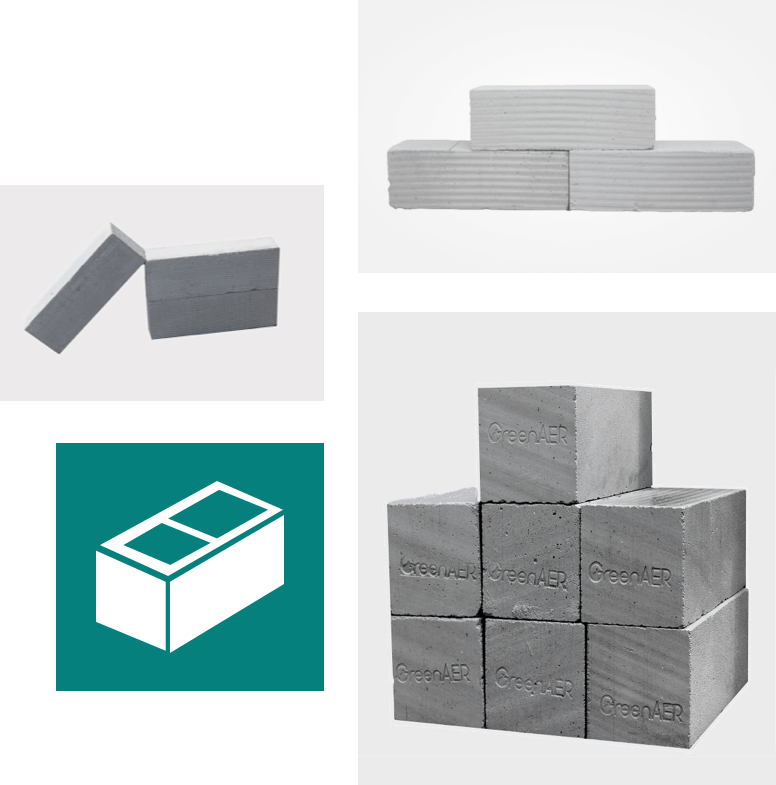

Blocks

GreenAer blocks are revolutionary building materials known for their lightweight yet robust structure. Composed of fly ash, cement, lime, water, and an expansion agent, AAC blocks undergo a unique autoclaving process, resulting in a cellular design that enhances insulation and reduces overall weight. These blocks offer eco-friendly benefits by using recycled materials and requiring less energy in production. With applications in residential, commercial, and industrial construction, Our blocks provide faster construction, excellent thermal insulation, and seismic resistance. Embracing AAC blocks signifies a commitment to sustainable and efficient building practice.

Advantages

Technical

Specification

| Density (oven dry) | 550-650 kg/m 3 |

|---|---|

| Compressive Strength | 4.0N/mm 2 |

| Thermal Conductivity | 0.16 W/mK |

| Sound Transmission class rating | 44db (200 mm wall) |

| Fire resistant | 4 hours (200mm wall) |

Do's & Don'ts for AAC Blocks

Do's

Do's

- Do add a stiffening column every three metres in length.

- Do use a saw to cut blocks

- Do install Tie bars at the junction of the wall or column and block at vertical distance 600mm from each other.

- Do use Mortar mixed in a ratio of 1:6. Use a notched trowel to apply the mortar.

- Do use Silicate cement

DON'Ts

DON'Ts

- Don't use AAC block walls for use in toilet and bathroom work. This is because AAC blocks are susceptible to moisture from sewage, rainwater and other

- Don't use a brick knife to cut blocks

- Don't use AAC blocks in load-bearing structures without the use of beams and columns as it can be dangerous.

- Don't use a 1:4 rich mortar when mixing your concrete, as this will cause the wall to shrink and create cracks.